Gasket Cutting Services

Why Choose Us?

Highly Accurate

Finishes to 0.05mm tolerances

No Tooling Needed

Allows for a fast set up

Highly Customisable

Virtually any material, shape or size

Quick Turn Around

Cutting speeds of 60m/minute

Tape Slitting

Latest single knife slitting technology

Cold Cutting Water Jets

Doesn't produce heat affected areas or burnt edges

Knife Cutting

Surgical precision cutting

Kiss Cutting

High accuracy, high quality precision cutting

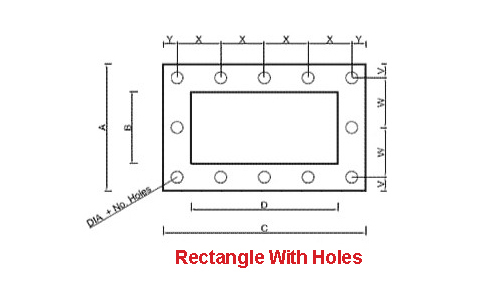

Gasket Type

test